In 1852, George Anderson, a member of the Glasgow Skating Club, published the following advice on skate sharpening under the pseudonym Cyclos:

The edges should … be kept sharp by occasional grinding, perhaps once in a season, or even less; and in doing it, the iron should be held across the face of the grindstone, which, by giving an almost imperceptible concavity, ensures a sharp edge.

Cyclos 1852, 34

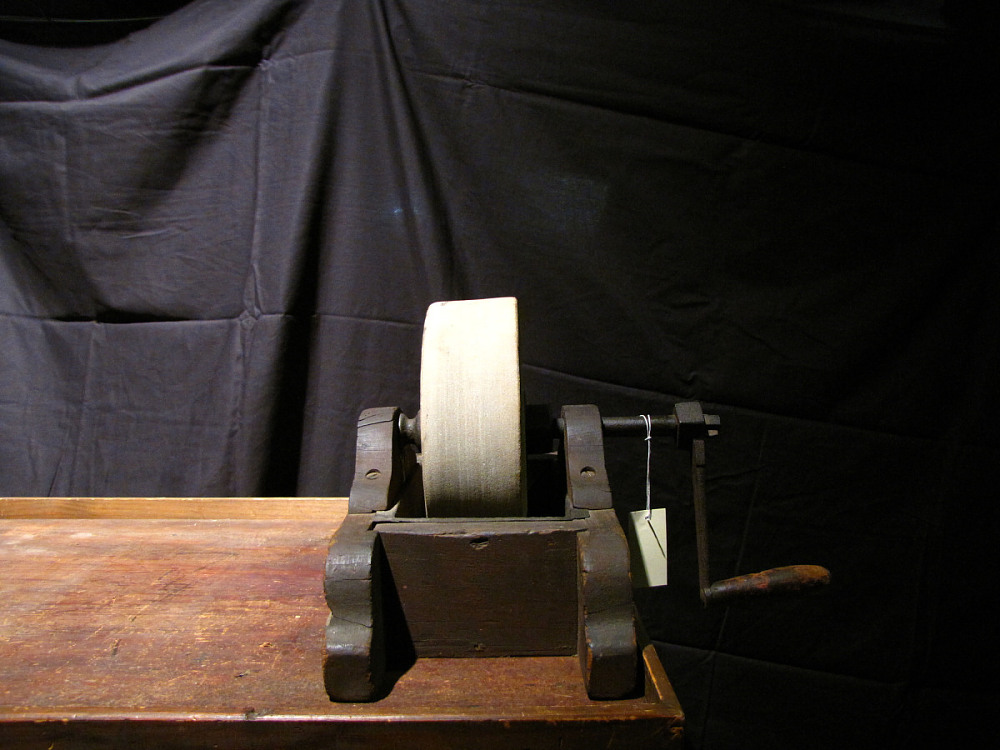

A grindstone, or grinding wheel in today’s metal shops, is the abrasive stone that forms the core of a bench grinder. The stone spins fast, grinding down the surface of whatever it comes in contact with (keep your fingers away!). This produces lots of hot sparks when grinding metal (including skate blades).

To sharpen a skate on this grindstone, you’d hold it sideways, with the toe pick pointing to the left and the heel of the blade pointing to the right, perpendicular to the stone. Then, you’d turn the crank (or have an assistant turn it) so that the wheel rotates counterclockwise. As the wheel spins, you’d slowly push the blade across the stone from left to right, starting with the toe and ending with the heel, then lift it up and repeat. After a number of strokes, the blade would match the curvature of the stone.

The radius of hollow this produces depends on the size of the stone. The one in the photo has a radius of about five inches. Five inches sounds like a really shallow hollow—too shallow even for figures, by today’s standards—but keep in mind that blades were wider then. Cyclos writes,

The lower surface of the iron should be a quarter of an inch broad or thereby.

Cyclos 1852, 34

The width of the blade makes a difference. (This is why ice dancers use deeper hollows than freestyle skaters—dance blades are narrower.) According to Sidney Broadbent, what you feel when your blade hits the ice is the bite angle, not the radius of hollow (ROH). This is the angle created at the corner of the blade by sharpening. Make it too small, and you skid. Too large, and you can’t stop. Broadbent gives an equation relating the ROH (R), blade thickness (T), and bite angle ($latex \theta$).

Broadbent 1997, I:2

$latex \sin\theta = \frac{T}{2R} &s=4$

T is the thickness of the blade, and R is the ROH. Today’s freestyle blades are about 0.15″ wide, so with a pretty normal 0.5″ ROH, the bite angle is about 8.6 degrees. For a patch blade with the same width and an ROH of 1″, the bite angle is about 4.3 degrees. Dance blades are narrower, about 0.11″ wide, so a 0.5″ ROH on a dance blade produces a bite angle of 6.3 degrees. This is why ice dancers prefer a deeper hollow.

Cyclos recommends blades that are much wider—0.25″. A five-inch ROH on a quarter-inch blade yields a bite angle of about 1.4 degrees, which is very shallow. It corresponds to a three-inch ROH on a modern patch blade, which is what Robert Ogilvie recommends for high-test skaters (1985, 111).

Conclusion: Cyclos’s recommendations are in line with late twentieth-century thinking on patch sharpening when differences in equipment are accounted for. I’ve neglected differences in ice, though, which do play a role.

To end, Cyclos warns readers of the dangers of learning on grooved skates, like those used for freestyle, dance, and recreational skating today:

it ought not to be grooved, as is sometimes done,—much to the detriment of the beginner, who, after learning on grooved skates, will feel himself like a cat on walnut shells when he puts on plain ones.

Cyclos 1852, 34

Skaters using patch skates for the first time may identify with this remark.

References

Sidney Broadbent. 1997. Skateology: A Technical Manual for Skaters Regarding Skates, Skating Fundamentals, Skate Sharpening. Revised ed. Littleton, CO: ICEskate Conditioning Equipment.

Robert Ogilvie. 1985. Competitive Figure Skating: A Parent’s Guide. New York: Harper & Row.

[…] (1877) gives a good description of how skates were sharpened using a grinding wheel. The grinding wheel does not produce a flat cross-section; instead, the blade’s curvature […]

[…] favorite chapter was the one on skate-making because it shows pictures of a skate being sharpened on a giant grinding wheel, a blade being forged, and other parts of the skate-making […]